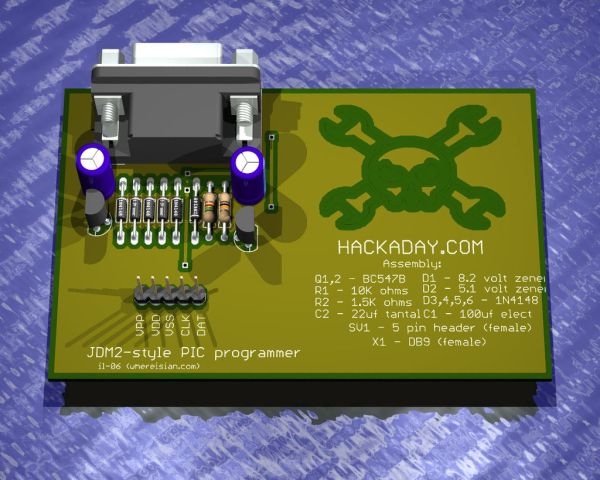

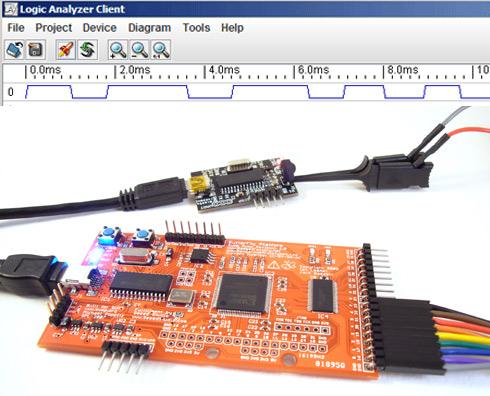

Openbench Logic Sniffer is an open source logic analyzer. It’s designed to support the SUMP logic analyzer software at the lowest possible cost. Download the source and design files from the Gadget Factory project page.

This project started in the comments on a post. Initial circuit design, PCB layout, development, and testing continued in the forum under the code name Project SUMP PUMP. Many, many people contributed ideas and advice, the Gadget Factory and Dangerous Prototypes coordinated circuit development and routed the PCB. We borrowed heavily from the Gadget Factory’s Butterfly Platform.

The Open Logic Sniffer is a purpose-built logic analyzer board designed to be low cost but high speed. It sacrifices a lot of the features you’d look for in a full-scale development board to achieve our primary goals:

- 70MHz+ sample speeds

- 32 channels

- 16 buffered, 5volt tolerant channels

- USB interface, USB powered

- USB upgradable everything

- Make it as DIY as possible

- Make it as open source as possible

- $30-$40 price range

We didn’t quite hit our initial price range, but we got really close.

You can get your own assembled Open Logic Sniffer at Seeed Studio for $45, including worldwide shipping. Continue reading about the design and collaboration below.

![Prototype Openbench Logic Sniffer logic analyzer]() Concept Overview

Concept Overview

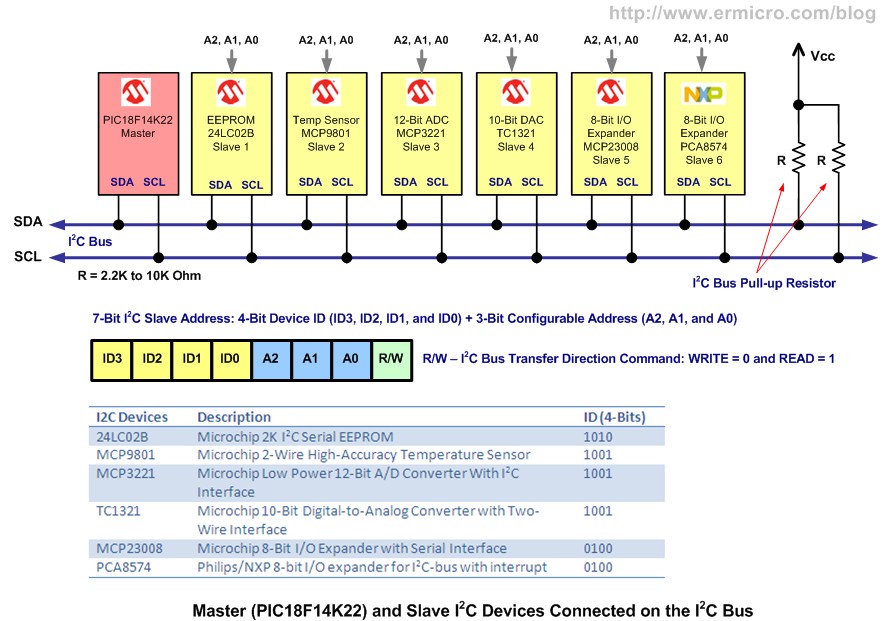

SUMP is an open source Java logic analyzer client by Michael Poppitz. It consists of two parts, a VHDL logic capture engine for FPGAs, and a Java logic analyzer client. The latest development version of the SUMP client is available from SourceForge.net.

SUMP is a sampling logic analyzer. It reads the state of the input pins and stores the samples in internal ram. It then dumps the samples back to the computer client for analysis. The number of samples possible is limited by the RAM in the FPGA.

We like SUMP because it’s the best developed open source logic analyzer toolchain currently available. It has lots of professional features like multi-stage triggers, configurable pre-roll, external trigger and clock sync, and a few protocol analyzers (I2C, UART). It’s open source, so the potential to add cool new features is limited only by your imagination and coding skills.

SUMP is typically ported to a general-purpose FPGA development board. We took a different approach and designed hardware specifically for SUMP, while constraining costs wherever possible.

Other logic analyzers

Professional logic analyzers have tons of channels and super high speeds. We’re not trying to make a low cost DIY version of these tools, the OLS isn’t an alternative to these types of tools if you need to sniff 100MHz+ signals and have huge sample sizes.

Being an engineer’s tool, there are plenty of DIY logic analyzer designs. Parallel port based logic analyzers used to be all the rage, but with parallel ports and direct interrupt access disappearing from systems, these are just historical curiosities.

Another type of DIY logic analyzer is a microcontroller-based device. There are several with custom interfaces like the PIC Logix, Scanalogic, and AVR Logic Analyzer. The Bus Pirate works with SUMP. Microcontroller analyzers all have one thing in common: they’re really slow, usually sub-megahertz.

USB IO chip-based hobby logic analyzers are currently popular. We’ve always been fans of the Saleae Logic, the USBee is similar. These devices are just a USB IO chip like a CY7C68013A-56PVXC, with all trigger and processing logic done in software on a computer. The hardware part is just a datalogger. The top sampling speed is usually around 24Msps (24MHz), if the conditions on your USB bus are just right. They can take ‘unlimited’ samples because everything is stored on the computer. Current models tend to be 8 channels, more channels would reduce the maximum speed proportionately. These are commercial products with highly polished user interfaces, we don’t know of any that are open source.

The Open Logic Sniffer sits somewhere between hobby analyzers and professional analyzers. The OLS samples up to 200Msps, regardless of the USB bus traffic, and has true hardware triggers. The OLS has twice as many buffered channels as most hobby USB analyzers, and four times more channels overall. The major difference is that the OLS has a limited number of samples, while the hobby USB analyzers can theoretically take infinite samples. Most of our debugging is done with the first few hundred samples, so this feature isn’t usually important to our work, your situation may be different. Future versions of the OLS will definitely have more sample storage, and we can work an infinite sampling mode into a future firmware update too.

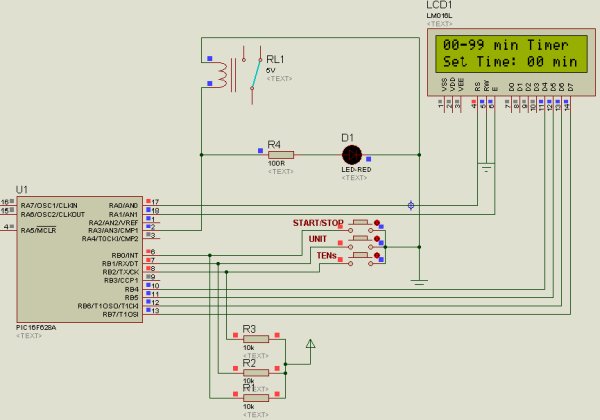

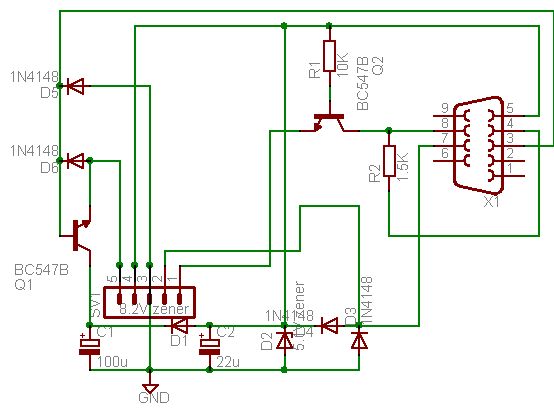

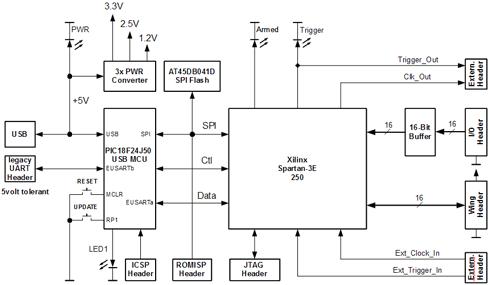

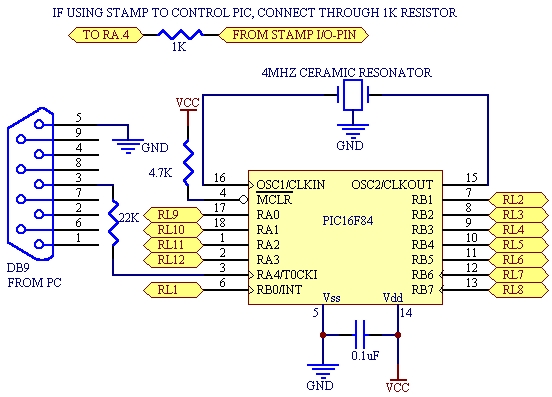

Click for a full size circuit diagram [PNG]. This circuit diagram, maintained by Uwe Bannow, shows the basic elements of the Open Logic Sniffer hardware. The FPGA captures logic samples from 32 input pins into internal RAM. The samples are dumped out a serial port for analysis on a computer. The open source SUMP logic analyzer client is used to capture and visualize the samples.

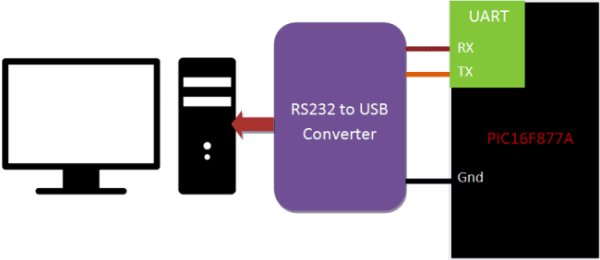

The FPGA only communicates over a serial port, so we used a USB microcontroller to convert the serial IO to a USB virtual serial port. The entire chain is upgradable through the USB connection. The microcontroller can program updated logic analyzer designs into the SPI flash data chip, and the microcontroller can also be updated from its USB bootloader.

We chose a USB microcontroller over a dedicated USB interface chip. A low pincount PIC was cheaper than most other USB bridge options. It’s USB 2.0 compliant, and can transfer data at up to 12Mbps. We’re using it with the completely open virtual serial port CDC interface, so it will work on almost any platform without proprietary drivers. The PIC can also implement other USB transfer protocols with a firmware update, faster connection methods can be supported when someone adds support for them to the SUMP client software.

Currently the SUMP FPGA design only transfers data over a 115200bps serial UART, the speed between the USB PIC and the computer isn’t a bottleneck. We routed several extra connections between the PIC and FPGA to implement a high-speed SPI interface in the future. The speed increase of an SPI interface can be supported in the SUMP client just by adding higher serial port speed settings.

An FTDI2232 chip was strongly considered as an alternative to the PIC. Here’s how we looked at it:

Benefits of the FTDI2232 with MSSP:

- JTAG interface to debug the FPGA

- SPI interface to program the ROM

- SPI and UART interface to the FPGA

Cons:

- Difficult to route

- Expensive to place

- Huge software development burden

- Needs special drivers

- USB interface not already supported by SUMP

With so much to accomplish already, major modifications to the client to work with untested hardware and custom drivers didn’t seem appealing. Not if the project were ever going to get finished. The PIC seemed like the best route for the first version.

Click for a large image of the schematic [PNG]. The schematic is divided into a microcontroller part [PNG] and a FPGA part [PNG]. These sections are where Ian and Jack initially split the design work. We used the freeware version of Cadsoft Eagle to make the circuit and PCB. Download the latest files from the Gadget Factory project page.

A Xilinx Spartan 3E field programmable gate array (FPGA) is the central component of the logic analyzer. The FPGA samples data from 16 buffered and 16 unbuffered IO pins, and stores the samples in internal RAM. The samples are later dumped out a serial UART to the PIC, and from the PIC to a computer via USB.

The basic FPGA schematic and PCB layout is taken directly from the Gadget Factory’s Butterfly Platform main board. The OLS shows how versatile the Butterfly Platform is as a development tool. The initial designs where first tested on the Butterfly Platform, and then we used the base design to create a unique, purpose-build hardware based on the prototype. You can get a Butterfly platform to build your own prototypes at the Gadget Factory for $99.

The FPGA (IC3) requires three different power supplies. The core requires 1.2volts and 2.5volts, and the IO pins run at 3.3volts. Each supply pin gets a 0.1uF decoupling capacitor (C11-26). We brought the JTAG programming and debugging connection to a header in the interior of the PCB. The JTAG header provides 2.5V to external JTAG programmers to satisfy the Spartan 3E’s requirements for 2.5V on the dedicated JTAG pins.

Several control and indication signals require special attention. INIT_B enables the FPGA when high, it’s held to 3.3volts with a 4.7K pull-up resistor (R6). The DONE signal goes high to indicate that the FPGA is configured and ready to use after a reset. It’s held to 2.5volts by a 300 ohm resistor (R1).

PROG_B, held at 2.5volts by a 4.7K pull-up resistor (R5), can be pulled low to put the FPGA in programming mode. The HSWAP pin (not shown) determines if all pins have pull-up resistors in programming mode. We grounded HSWAP so that all pins have weak pull-ups when PROG_B is low.

FPGAs are volatile programmable chips, they lose their configuration without power. The FPGA configuration, called a bitstream, has to be loaded into the chip each time it starts. We configured the FPGA to automatically load a bitstream from an SPI ROM chip by wiring the mode select pins as follows: M0(3.3volts), M1(0volts), M2(3.3volts).

The FPGA runs from a 50Mhz oscillator(Q2). This is a complete clock generation module, no external capacitors are required. The 50Mhz clock is doubled to 100Mhz by an internal Digital Clock Manager (DCM) to provide the 100Mhz clock required by the VHDL core.

Two LEDs indicate the FPGA status. The ARM LED indicates when a trigger is set and the device is actively waiting for the trigger. The TRIG LED indicates when a trigger has been activated. We used 390R current limiting resistors (R8, R9) on the prototype, but the assembled board should ship with 1K1 resistors to make the LEDs dimmer.

The FPGA IO pins are powered by 3.3volts, and can tolerate no more than a 3.3volt signal. The M74LCX16245DTR2G buffer (IC4) allows 16 buffered pins to sniff 5volt logic and can tolerate voltages from -0.5 to +7V. This chip is also powered by the 3.3volt supply, and it gets a 0.1uF decoupling capacitor (C9) on the supply pin.

The logic analyzer can sync with other test equipment and should allow OLS’s to be daisy chained together for more channels. It can be driven by an external clock and trigger, and it also outputs its internal clock and trigger. You can tap these signals from the some-what awkwardly placed pin block in the middle of the PCB. The external clock input had to be on an FPGA global clock pin, this was the best possible location to access it because no sensitive high-speed signals were routed across other traces.

Awing is an accessory for the Gadget Factory Butterfly Platform development board. It uses a standardized header and pinout. The header has 16bits of 3.3volt IO, and 2.5, 3.3, and 5volt power supplies.

We added a wing header to the OLS so it can use accessories developed on the Butterfly Platform, like a digital sampling oscilloscope. This has the added benefit of making the OLS compatible with a bunch of existing Butterfly Platform accessories.

The FPGA programs itself with a bitstream stored in a 4Mbit AT45DB041D SPI flash storage chip (IC2), we refer to it as a ROM. We previously demonstrated this chip with the Bus Pirate. It’s powered by the 3.3volt supply, and requires a 0.1uF capacitor (C10) on the supply pin. The XC3S250E bitstream will fit into a 2Mbit flash chip, but only 4Mbit chips were available when we sourced parts.

The ROM chip has an SPI interface that connects to the FPGA, the PIC microcontroller, and an external programming header.

- The FPGA mode select pin configuration causes the FPGA to load a bitstream from the ROM chip. When the bitstream is finished loading, the DONE signal goes high, and the FPGA is programmed and active.

- The PIC can (re)program the ROM with updated bitstreams. The PIC holds the FPGA PROG_B line low in this mode so the FPGA releases control of the ROM chip.

- The external header can be used to program the ROM from a programmer. Place a jumper between the PGM and EN pins to manually place the FPGA in programming mode.

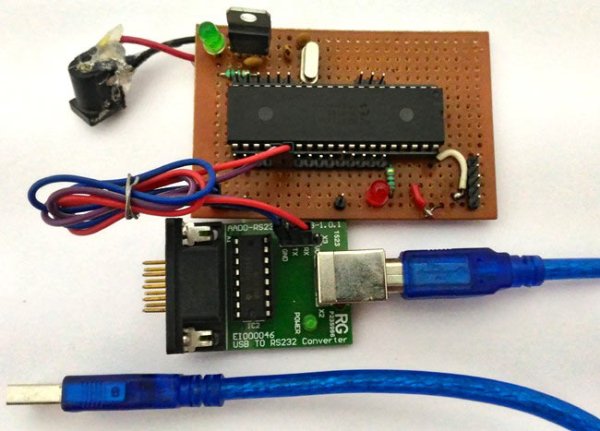

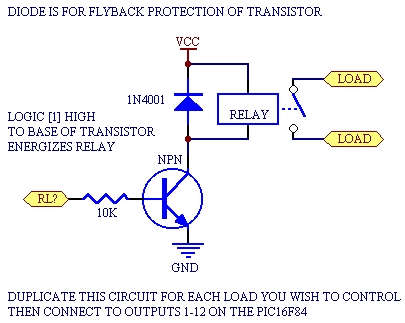

A PIC 18F24J50 microcontroller (IC1) is the interface glue. It has these functions:

- Provides a USB->serial connection from the SUMP Java client to the SUMP hardware in the FPGA

- Puts the FPGA in programming mode and updates the ROM with a new bitstream

- A USB bootloader can be used to update the PIC firmware

The 18xxJxx chips are really interesting, and seem like a hybrid of the 24F and 18F families. This PIC has the instruction set and 8bit core of the 18F family, but many enhanced features of the 16bit PICs. Half of the UARTs and SPI modules are assigned with peripheral pin select, it has flash configuration words, and it runs on 3.3volts, like a 16bit PIC.

The PPS features are really handy and make the clean layout of the PCB possible. The ROM SPI connection and FPGA UART connection are both assigned to custom pins with PPS. PPS can be used to implement a high-speed (10Mbit+) SPI connection between the PIC and FPGA in a future firmware upgrade.

The PIC is powered by 3.3volts, the supply pin gets a 0.1uF capacitor (C7). The USB peripheral has a separate 3.3volt supply pin that also needs a 0.1uF decoupling capacitor (C8). A 10uF capacitor (C4) is required for the internal 2.5volt core supply regulator.

An external oscillator provides an accurate USB clock, we used a 20MHz crystal (Q1) and two 27pF capacitors (C5, C6).

A 10K resistor (R3) holds the PIC reset pin high for normal operation, the RESET button (S1) grounds it to cause a hard reset. A second button (S2, R4) is available for simple user input.

The LED ACT is a general purpose indicator LED controlled by the PIC through current limiting resistor R7. The PWR (power) LED is connected to the USB supply though current limiting resistor R2, it illuminates whenever the board is powered.

We also brought the one of the hardware UARTs to a header. The pins are 5volt tolerant, and can be interfaced at up to 5volts without damaging the PIC. This header can be used for a ‘classic’ serial port connection. The board can also be powered through the UART header supply pins.

The board is intended to be powered by the 5volt supply from a USB port. Three regulators provide the three supply rails required by the circuit. All the chips require a 3.3volt supply (VR1), the FPGA also requires a 1.2volt (VR3) and 2.5volt (VR2) supply. As recommended by the datasheet, there’s a 10uF capacitor (C27) on the supply line, and each regulator has a 1.0uF capacitor (C1-3) on the output pin.

Numbering

The OLS has two different numbering schemes, one on the inside of the board and one on the outside of the board. The inside numbering scheme starts with zero on the buffered header. The outside numbering scheme starts with zero on the Wing header. Currently the numbering scheme can be selected by loading a bitstream that implements either numbering scheme. Future updates will support selecting the numbering scheme through the Java Logic Analyzer client.

We used the freeware version of Cadsoft Eagle to make the schematic and PCB. Download the latest files at the Gadget Factory project page.

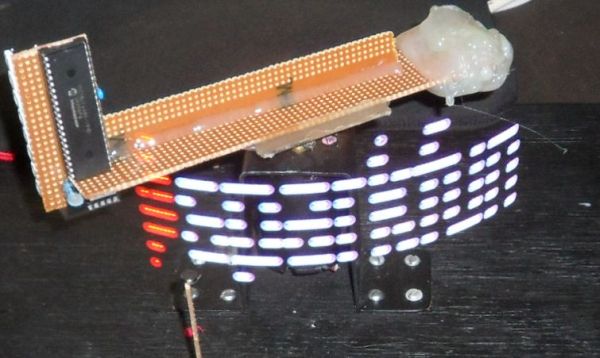

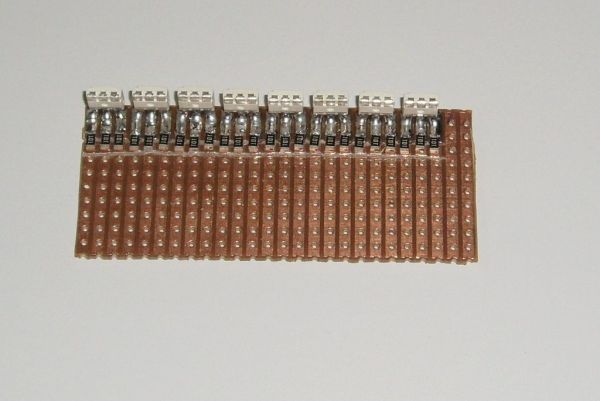

The PCB is nearly the maximum allowable size in Eagle. All the components are surface mount, but we stuck with traditional through-hole headers. It took us an hour or two to solder each prototype board by hand.

We had boards made with the $50 Seeed Studio Fusion board service. This design probably would have been ready a bit sooner, but the PCBs were delayed about a month by the major Hong Kong Post Christmas mail rush.

Click for a full size placement image [PNG]. Uwe Bannow generously provided parts for the OLS prototypes. An extra special thanks to Uwe, his help was key to making this project what you see today.

|

Part

|

Quantity

|

Value

|

Package

|

|

C1-C3

|

3

|

|

0805

|

|

C4,C27

|

2

|

|

SMC_A

|

|

C5,C6

|

2

|

|

0805

|

|

C7-C26

|

20

|

|

0603

|

|

IC1

|

1

|

|

SO-28W

|

|

IC2

|

1

|

|

SO-08W

|

|

IC3

|

1

|

|

VQ100

|

|

IC4

|

1

|

|

TSSOP48

|

|

J1

|

1

|

|

SMD

|

|

LEDs

|

4

|

|

0805

|

|

Q1

|

1

|

|

HC49UP

|

|

Q2

|

1

|

|

OSC1

|

|

R1

|

1

|

|

0805

|

|

R2

|

1

|

|

0805

|

|

R3,R4

|

2

|

|

0805

|

|

R5,R6

|

2

|

|

0805

|

|

R7-R9

|

3

|

|

0805

|

|

S1,S2

|

2

|

|

DTSM-6

|

|

VR1

|

1

|

|

SOT23-5

|

|

VR2

|

1

|

|

SOT23-5

|

|

VR3

|

1

|

|

SOT23-5

|

|

JP7,JP8

|

2

|

|

1X09

|

![Prototype Openbench Logic Sniffer logic analyzer]() SUMP FPGA design

SUMP FPGA design

Get the latest project files from the Gadget Factory project page. The original SUMP project is licensed under the GPL, you can get it at SUMP.org.

OLS Design Changes

The OLS uses the open source (GPL) SUMP logic analyzer VHDL design. It’s synthesized with the free Xilinx ISE Web Pack tool suite. Our design is based on Jonas Diemer’s Spartan 3E SUMP port [ZIP]. The following modifications were made for the OLS hardware:

- A new ucf (User Constraint File) was generated to map the pins of the FPGA to the layout of the OLS board and to support multiple numbering schemes.

- Support for outputting the sample clock to an external pin was added.

- Support for adding an external pin as a trigger was added.

- Added support for Trigger and ARM LED’s.

- Files for multiple BRAM memory configurations were added. The files were generated with the Xilinx Core generator and are Xilinx specific.

Memory

The OLS utilizes BRAM (Block Ram) that is embedded inside the Spartan 3E FPGA, the included XC3S250E chip has 216K of BRAM available. There are six bitstreams that allocate the available memory into different combinations of memory depth and sampling channels. Currently the following memory/channel configurations are available:

- 32 channels with 4k sample depth.

- 16 channels with 8k sample depth.

- 8 channels with 16k sample depth.

You may have noticed that the above numbers don’t add up to the 216K of BRAM that is available. With 8 channels we should be able to get 216k/8 = 27k samples. The first issue is that the published size of 216K of BRAM includes parity bits, without parity bits we actually have 192K of BRAM available. The second issue is that the Sump design is setup to require a power of 8 for its sample depth, so until the Sump design can be modified we are stuck with the above power of 8 sample depths. Once these two issues are resolved the possible memory/channel configurations will be:

- 32 channels with 6k sample depth.

- 16 channels with 13k sample depth.

- 8 channels with 27k sample depth.

Our future design plans do include working on adding 32-64Mb of SDRAM memory.

Bitstreams

The output of the Xilinx Webpack synthesis tools is a bitstream file that is used to configure the FPGA. We convert the bitstream (*.bit) file to an Intel Hex format (*.mcs) using the Xilinx Impact application. The bitstream is then loaded, by the PIC, into the Atmel SPI Flash chip. When power is applied to the OLS the FPGA configures itself by loading the bitstream from the SPI Flash chip.

There are currently six different bitstreams that provide for 3 different memory configurations and 2 different numbering schemes. Currently, the bitstreams have to be loaded with the pump-loader executable. Future revisions will load the desired bitstream from the Java Logic Analyzer client.

For more detail: Prototype Openbench Logic Sniffer logic analyzer

The post Prototype: Openbench Logic Sniffer logic analyzer using pic microcontoller appeared first on PIC Microcontroller.

![Mädchen Machen Technik]()